MRI – DFT -1

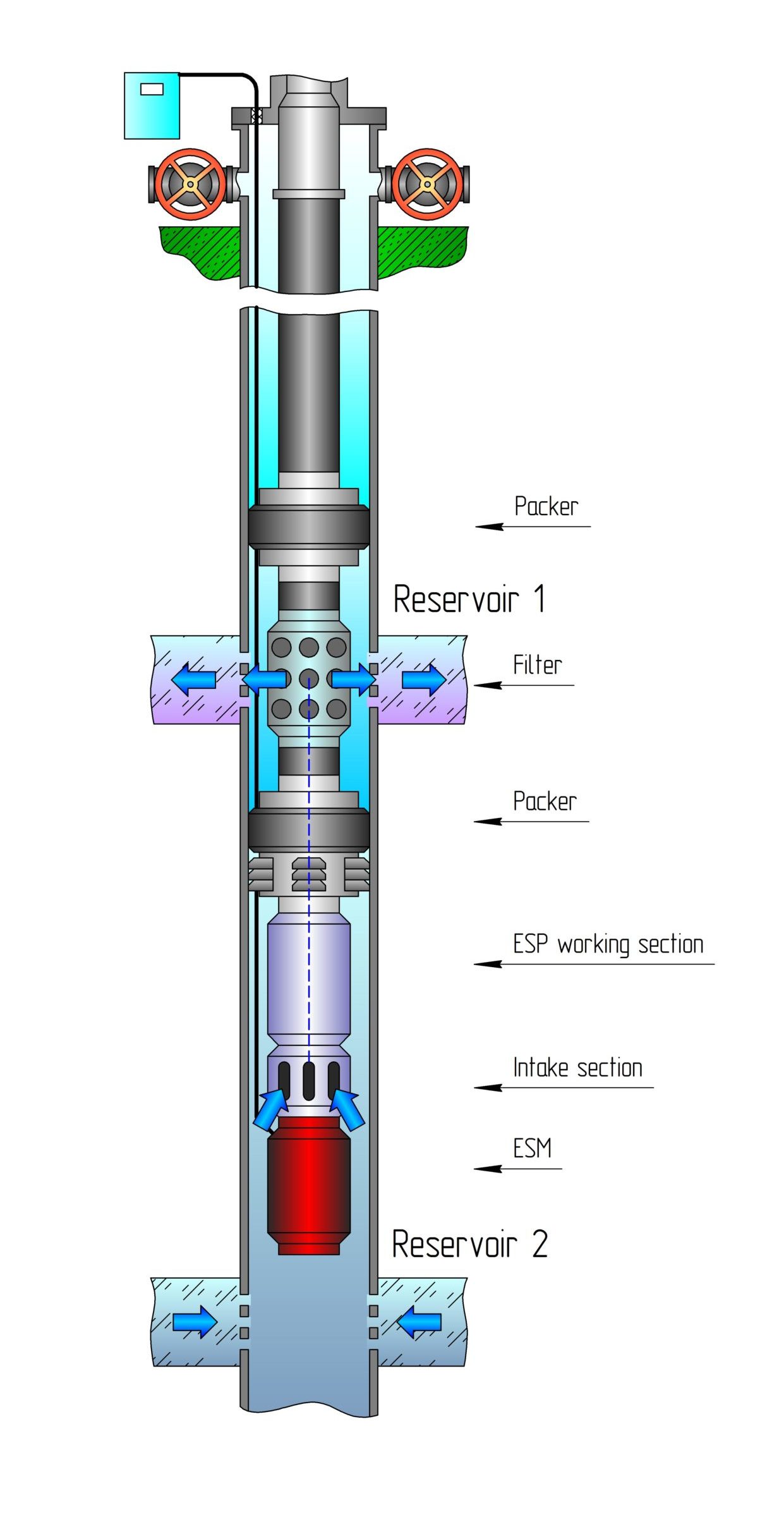

This patented completion system includes two packers used for simultaneous-separate withdrawal of formation water from the lower reservoir and injection into the upper reservoir of one well using ESP. The reservoirs are isolated by two mechanical packers with a cable inlet, that ensures the connection of the logging cable of electric submersible motor (ESM) and downhole fluid transfer (DFT) between the reservoirs.

Applications:

- For cost reduction in multi-reservoir fields and waterflood injection wells penetrating reservoirs with different properties;

- To use currently inactive wells and reservoirs for reservoir pressure maintenance;

- Organization of reservoir pressure maintenance at remote fields;

- Location of waterflood injection wells in areas with difficult terrain;

- Absence of water treatment points for reservoir pressure maintenance in the very area.

Benefits:

- Ability to control flow rates of injected liquids;

- No additional equipment for well operation is required due to ease of installation and high performance of the system;

- Creation of pressure maintenance system without installation of high-pressure water pipelines and construction of pumping stations;

- The system is run and set in the well in one stage.

| Item code | Casing string, mm./in. | Pressure differences at CEV,

MPa/psi |

Maximum T, ℃/F | Tubing thread size,

mm/in |

Downhole environment | |

| Nominal diameter | Wall thickness | TMU w/gauges | ||||

| MRI – DFT -1-118 | 140/5.51 | 6-8/

0.2-0.3 |

35/5076 | 120/248; 150/302 ⃰ | 73/2.87 | Oil

Associated gas Gas Condensate Natural gas Formation water |

| 146/5.74 | 9-11/

0.35-0.43 |

|||||

| MRI – VDFT-1-120 | 146/5.74 | 6,5-10/

0.23-0.39 |

35/5076 | 120/248; 150/302 ⃰ | 73/2.87 | |

| MRI – DFT -1-140 | 168/6.61 | 8-11/

0.3-0.43 |

35/5076 | 120/248; 150/302 ⃰ | 73/2.87 | |

| 178/7 | 13-15/

0.51-0.59 |

|||||

| MRI – DFT -1-145 | 168/6.61 | 7,3-8/

0.27-0.31 |

35/5076 | 120/248; 150/302 ⃰ | 73/2.87 | |

| 178/7 | 11,5-12,7/

0.43-0.47 |

|||||

* by personal request