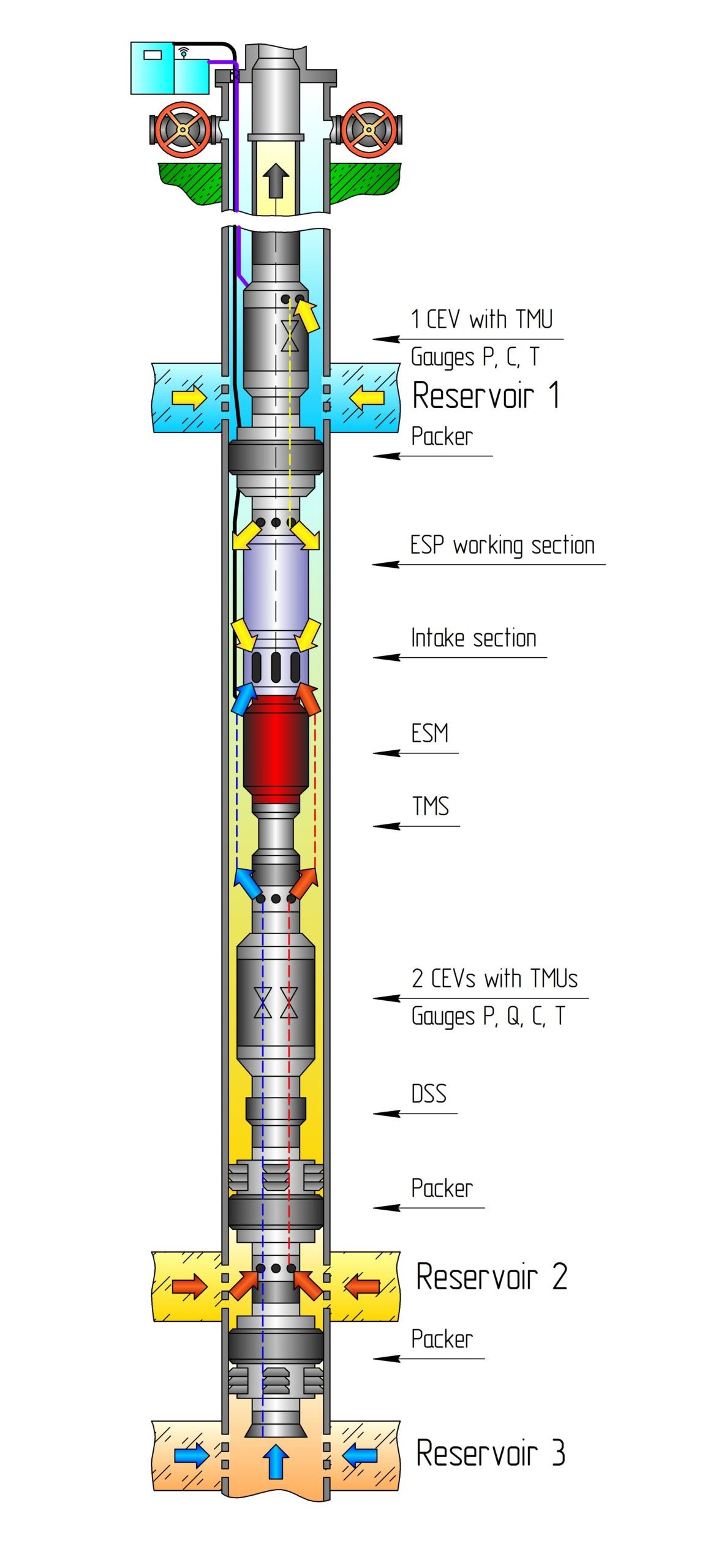

MRP-3CEV-3TMU

This patented remotely controlled completion system used in multi-reservoir production (MRP) includes three packers and an ESP unit for simultaneous production from three reservoirs through a single-tubing string. The system provides parameter measurement and flow control separately for each of the three fluid flows entering the section of an ESP.

Applications:

- For cost reduction in multi-reservoir fields and wells penetrating reservoirs with different properties;

- For solving problems associated with drawdown pressure limits or negative mutual interference between reservoirs;

- For simultaneous production from multiple reservoirs with different physicochemical properties, production fluid characteristics, water cuts, gas-oil ratios, bubble-point pressures and temperatures.

Benefits:

- The entire system, including controlled electric valves (CEV), is controlled in real time remotely or from Geonik‘s control station;

- Two-way communication to obtain fluid data from the two lower telemetry units (TMU) with Р, Q, C and T gauges and precise opening and closing regulation of electrovalves during operation of an ESP unit from Geonik‘s dedicated telemetry system (TMS) or through power or logging cable by personal request*;

- Two-way communication to obtain fluid data from the upper telemetry unit (TMU) with Р, C and T gauges and precise opening and closing regulation of CEVs during operation of an ESP unit through logging cable;

- Dynamic testing of each reservoir during ESP operation with recording of pressure build-up curves by shutting in one of the reservoirs;

- This three-packer system is run and set in the well in two stages: (1) setting the lower two-packer system and (2) running three CEVs with their TMUs, an ESP unit and a packer for connection to the lower two-packer system;

- Real-time management of each reservoir using downhole gauge and flow-meter data from CEVs and TMUs;

- To change an ESP, the main system including the upper packer is retrieved from the well without the lower two-packer system;

- No additional tubing used for production from multiple-completion wells with hydraulic valves is required due to ease of installation and high performance of the system.

| Item code | Casing string | CEV seat diameter mm/in | CEV working pressure MPa/psi | Maximum temperature °C/F | Tubing thread diameter mm/in | Downhole environment | ||

| Nominal diameter mm/in | Wall thickness mm/in | TMU w/gauges | TMS | |||||

| MRP-3CEV-3TMU-118 | 140/5.51 | 6-8/0.2-0.3 | 12/0.47; 20/0.78 ⃰ | 30/

4351 |

120/248; 150/302 ⃰ | 150/

302 |

73/2.87 | Oil

Associated gas Gas condensate Natural gas Formation water |

| 146/5.74 | 9-11/0.35-0.43 | |||||||

| MRP-3CEV-3TMU-120 | 146/5.74 | 6,5-10/

0.23-0.39 |

12/0.47; 20/0.78 ⃰ | 30/

4351 |

120/248; 150/302 ⃰ | 150/

302 |

73/2.87 | |

| MRP-3CEV-3TMU-140 | 168/6.61 | 8-11/

0.3-0.43 |

12/0.47; 20/0.78 ⃰ | 30/

4351 |

120/248; 150/302 ⃰ | 150/

302 |

73/2.87 | |

| 178/7 | 13-15/

0.51-0.59 |

|||||||

| MRP-3CEV-3TMU-145 | 168/6.61 | 7,3-8/

0.27-0.31 |

12/0.47; 20/0.78 ⃰ | 30/

4351 |

120/248; 150/302 ⃰ | 150/

302 |

73/2.87 | |

| 178/7 | 11,5-12,7/

0.43-0.47 |

|||||||

* by personal request